Over the years, I’ve owned a couple of band saws, but getting the saws to work at their best was always questionable. I started with a Delta 14” from the around 1990, new in the box. It worked ok, but it didn’t quite do what I’d both expected nor truly wanted. I started out going through all of the setup processes, to make sure the saw itself was tuned properly. After that, I tried different types/brands of blades, in an attempt to find the missing piece to my puzzle. Some of the blades were better than others, but even the best I’d tried was still not providing what I was after. I transitioned towards working with some larger pieces of wood, and finally decided to move up to a larger capacity saw. My new saw had the ability to properly tension all the way up to a 1” blade, which was completely different than my old Delta.

Over the years, I’ve owned a couple of band saws, but getting the saws to work at their best was always questionable. I started with a Delta 14” from the around 1990, new in the box. It worked ok, but it didn’t quite do what I’d both expected nor truly wanted. I started out going through all of the setup processes, to make sure the saw itself was tuned properly. After that, I tried different types/brands of blades, in an attempt to find the missing piece to my puzzle. Some of the blades were better than others, but even the best I’d tried was still not providing what I was after. I transitioned towards working with some larger pieces of wood, and finally decided to move up to a larger capacity saw. My new saw had the ability to properly tension all the way up to a 1” blade, which was completely different than my old Delta.

The blade that came with my MiniMax was just something to allow it to cut, but wasn’t providing super results. After trying a number of blades, I happened to be in Atlanta for one of our events, so we stopped at the Highland Woodworking store. Wow, what an amazing store, and a huge selection of band saw blades. I spoke with one of the folks working at Highland and asked for their recommendation on a band saw blade. After finding how I was intending to use my saw, they suggested I try one of the Wood Slicer blades. I had read about this brand of blade, but since I’d never used one, I decided I’d just get a single blade to try it out. I picked up a 1/2” blade with a 3/4 teeth configuration, which would allow multipurpose use. I wanted this for both some curved work (not like a scroll blade, think more like the gentle curves on a guitar), as well as taking small log sections and cutting them into bowl blanks.

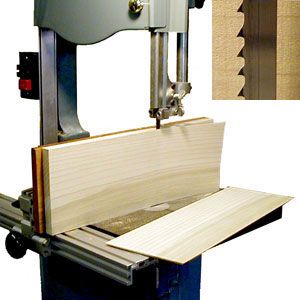

When I got back home, I set the new blade to the side, as I was doing some ripping operations and my 1” blade was doing OK. Well, that didn’t last too long. My 1” blade is the one that came with my saw. It was cutting very similar to how it had always cut, since I’d purchased the saw. All of a sudden, there was a bang, and the blade was gone from sight. I’d actually broken it. After pulling the old blade from my saw, I made sure there was no damage to the saw and especially the tires. Luckily, all was fine. Time to try out my new Wood Slicer blade. After installing the blade, and tensioning it properly, I was ready to finish up the ripping. As soon as the blade touched the wood, I knew I’d received some great counseling from Highland’s staff. This Wood Slicer was completely amazing. I was cutting some 8/4 maple and then some 6/4 oak, both of which the blade treated as if it was cutting butter. Seriously. I was completely dumbfounded. I’d never experienced anything like this on either my 14” or my 16”, no matter what blade I’d used. I was having one of those moments, when I sit back and wonder where a tool has been all of my life. This Wood Slicer blade absolutely fit into one of those moments.

There is no doubt I’ll continue to buy the Wood Slicer blades for my saw, for all but possible super specialized cutting. I wish I’d tried one of these in my Delta, as I’m sure it would have elevated its results as well. Just in case someone reading this article also has a MiniMax 16, the info on the blade wrapper is as follows: 154 1/2 022 3/4T HP #51004002.

I hope to see some of you at our upcoming events, listed on the Lie-Nielsen website. Feel free to come up and say hi. Also, feel free to contact me if you have any questions, or if you have suggestions for future articles you would like to see.

Really good job on the site, Keep up the good work!

Thank you so much about sharing!!! great post