10 out of 10 bandsaws prefer them

![]() In your catalog you’ve said more than once that “making the wheels coplanar” on a bandsaw is an important part of tune-up, but as far as I know you haven’t described how to do it. I have just a few questions: what is it, how do I know if I need it, and if so how do I do it?

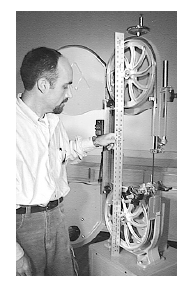

In your catalog you’ve said more than once that “making the wheels coplanar” on a bandsaw is an important part of tune-up, but as far as I know you haven’t described how to do it. I have just a few questions: what is it, how do I know if I need it, and if so how do I do it?

![]() Hmm. Seems we’ve left a few details yet to cover, eh? The object of the exercise is to make your two bandsaw wheels lie in the same plane while you’re cutting wood. When your wheels are coplanar, blades tend to track stably, and perhaps best of all there’s little or no adjustment required when you change blades. It’s much more likely that your blade will be perpendicular to the saw table, and your upper guides are less likely to require adjustment when you change depth of cut significantly.

Hmm. Seems we’ve left a few details yet to cover, eh? The object of the exercise is to make your two bandsaw wheels lie in the same plane while you’re cutting wood. When your wheels are coplanar, blades tend to track stably, and perhaps best of all there’s little or no adjustment required when you change blades. It’s much more likely that your blade will be perpendicular to the saw table, and your upper guides are less likely to require adjustment when you change depth of cut significantly.

Are your saw’s wheels out of plane? A snap diagnosis might be easy: if you have to fiddle with the saw’s tracking knob every time you change blades, you are going to benefit distinctly from making the wheels coplanar. If you’re not sure, here’s another quick check: if there’s a blade on your saw now, go look at it. Is it in the same position on the upper wheel as on the lower? If you can see a difference without measuring, then your wheels are almost certainly running in different planes.

If you’re not sure, here’s another quick check: if there’s a blade on your saw now, go look at it. Is it in the same position on the upper wheel as on the lower? If you can see a difference without measuring, then your wheels are almost certainly running in different planes.

Put a 1/2″ blade on your saw and tension it as if for work. Don’t bother tracking it; you’re just going to take it off again in a minute. Lay a 4 ft. straightedge against the lower wheel, as close to the center as possible. With the straightedge touching the wheel’s rim at both top and bottom, check the upper wheel. Use the tracking knob as needed to make the rim parallel to the straightedge. If the upper wheel doesn’t touch the straightedge, or if it pushes the straightedge out of contact with the lower wheel, then adjustment is called for.

On Delta and Jet bandsaws, the upper wheel can be moved outward by dismounting it and installing a 5/8″ i.d. spacer on the shaft. A hardware store 5/8″ washer will work if you need to move the wheel at least 1/16″. Some hardware stores stock machine bushings, narrow-rim washers available in a variety of useful thicknesses. Be sure the bushing already on the shaft is reinstalled last, just before the wheel. On Sears 12″ and Inca 10″ saws, the lower wheel can be moved by unlocking a set screw and shifting the wheel on its shaft. For other saws, have a good squint and figure out which wheel is adjustable.

It’s easy to set the wheels coplanar, and the payback is mighty convincing. When you can put any blade on your saw, tension it and turn on the saw without worrying about tracking, you’ll be a believer, too.

Visit Highland Woodworking’s Library for more tool tips and information.