Some of our bloggers are still working on their 2015 Holiday Woodworking Tool Wish Lists. Just in case you are still working on yours (or haven’t even started yet!), here are some ideas to get you going. And don’t forget to create your own woodworking wish list on our website by CLICKING HERE.

Today we’ve got a wish list from Highland Woodturner contributor, Curtis Turner:

- Oneway Wolverine Mini-Platform Assembly

There are times when I want to sharpen smaller tools on my grinder. The larger (standard) Wolverine platform can make it difficult to maneuver small tools. The mini-platform is 3-1/4″ x 2-1/4″ and has a curved front edge for easier access with short tools. This platform fits in the Wolverine base. - Old-Fashioned Milk Paint Barn Red – Quart

I have been working more with milk paints and want to try out this particular color. Milk paints are water based. The paint can be mixed in small batches. The paint is a power that can be mixed with other colors to create your own unique color. Milk paint can completely transform the appearance of any project. - Auriou Riffler 6” flat V and rectangular in 14 grain

I recently purchased an Auriou 10” knife and spoon riffler in 10 grain. I have found it to be very useful. For example, I have used it to remove the nub on the bottom of bowls. This worked perfectly! I think a smaller riffler with a finer grain would be a perfect follow up to my 10” riffler. Auriou rasps are graded by grain. The higher the grain number the finer the surface left by the tool. - Double Outside Caliper – 4 inch

This double caliper helps to determine the wall thickness for bowls and other similar items. These help ensure a consistent wall thickness. This looks like the perfect size for small bowls. I have a giant double caliper. It is so large that I do not often use it on smaller items. - Earlex Steam Generator

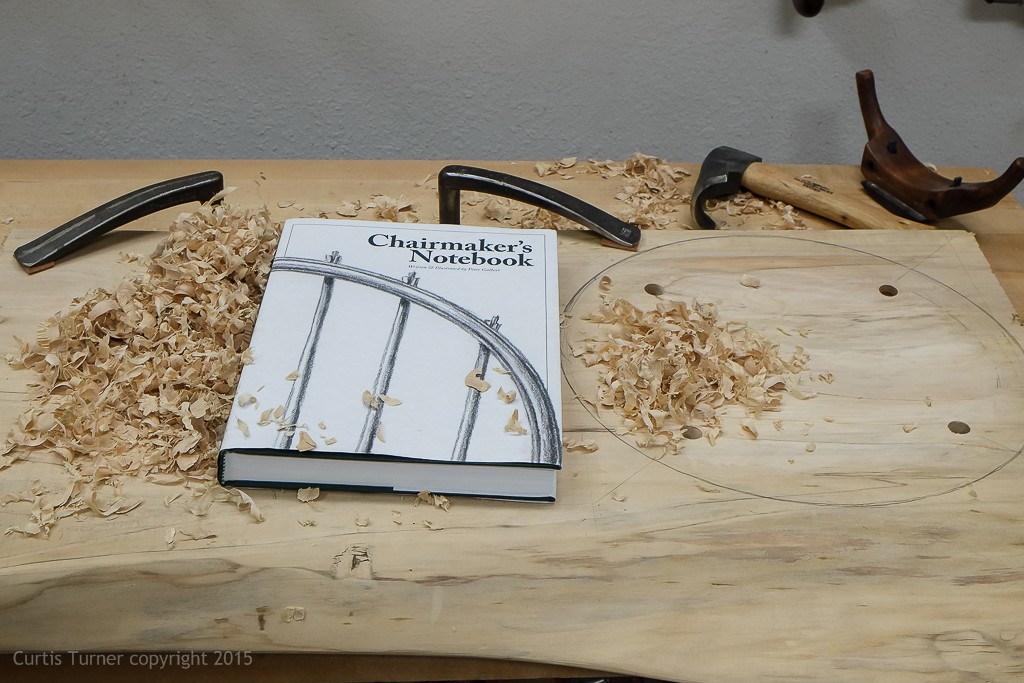

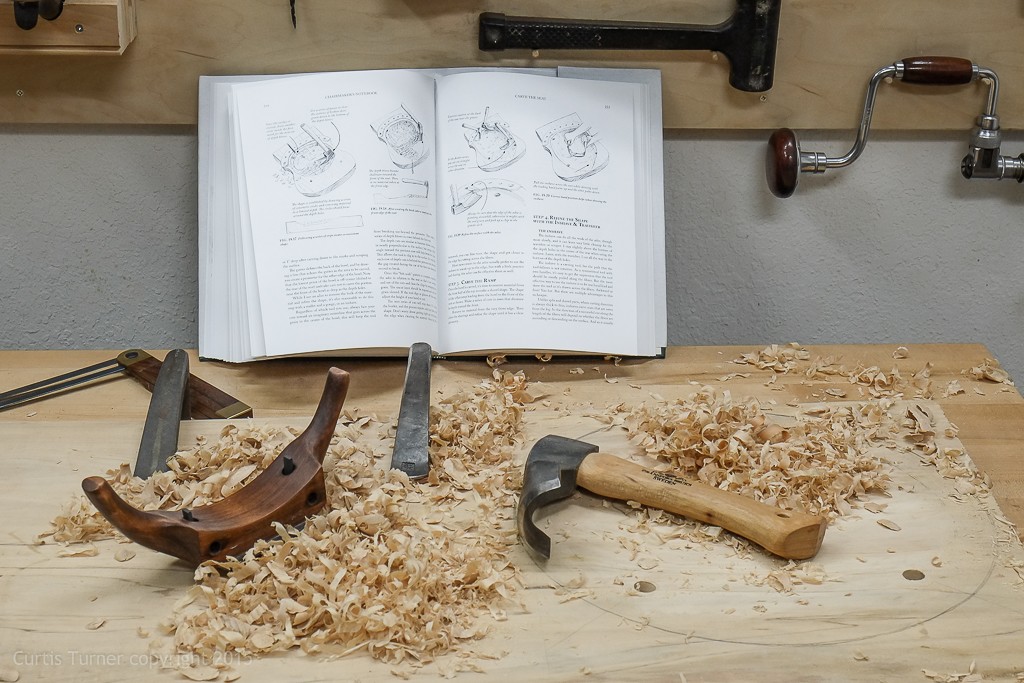

I want to try my hand at making a Windsor chair. This generator will allow me to steam wood for bending the back or bent arms of a Windsor chair. This is a small 8″ x 12″ unit and uses a 120v current. The manufacture states “Providing plenty of steam for a small to medium homemade steam box, our tests with this unit had it making steam in just 23 minutes & then heating up our homemade 6″ diameter x 62″ long PVC steam box (tube) to 212° in another 10 minutes.”

Curtis was the 2012 President of Central Texas Woodturners, a member of the American Association of Woodturners, and a member of Fine Woodworkers of Austin. Curtis teaches and demonstrates nationally for Lie-Nielsen Toolworks. He also owns a studio where he teaches and works. Curtis lives and works in Central Texas with his wife and four young children. Take a look at his website at www.curtisturnerstudio.com.