Are They Any Good?

So, I’ve spent the last week using Stanley’s reissue 750 socket chisels in sizes 1/8″, 1/4″, and 3/4″. I didn’t set up any arbitrary test criteria or elaborate measuring devices to determine who knows what. All I did is what I normally do with chisels during a workday in my cabinet shop. You know, pare chamfers, clean out glue glops, chop joints and open paint cans. I’m kidding about the paints cans. For that I use a pocketknife.

Over the years I’ve decided I want 4 things in a new bench chisel. It has to be well machined from the factory – I can’t afford to spend the entire day tuning it up. It must stay sharp for a reasonable amount of time – The edge can’t deform every time I hit it with a mallet. The handles have to be comfortable and not prone to splitting or breaking. I’d like the tool to look nice as well. I think a little care in form and design adds to the innate pleasure of using a fine tool.

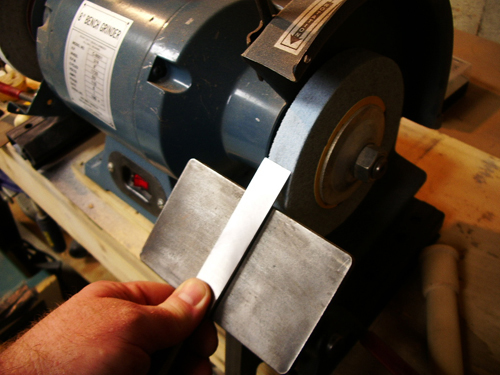

As I mentioned above, I found these new 750s to be well machined out of the box. I got the backs flat quickly. You’d expect this from a premium tool. Were they as perfect in form as, say, the Lie-Nielsen’s? No, but the lower price of the Stanley’s adequately reflects this. After the initial sharpening, I only had to touch up each edge on either a strop charged with honing compound or my 8000 grit water stone during this evaluation. This seems right to me based on my experience with other premium chisels. They definitely held up better edgewise than any of the economy line chisels I own. Now all this is purely anecdotal on my part of course, but I feel I’ve gained a good grasp over the years on how long a chisel edge should last. As for the handles not splitting, only time will tell. Hornbeam is pretty tough stuff after all. In my opinion, nothing beats a socket chisel for looks and longevity. Socket chisels are definitely worth the extra money compared to say a tang fitted handle.

Bottom line? I’m enjoying Stanley’s new 750s. I feel the price to quality ratio is certainly there. They are a great option if you’ve always wanted a set of socket chisels and either couldn’t find the originals or afford the ones on the used market. You’ll have to spend a little more time on these to get them pretty if that’s important to you, but you’ll save money. I, for one, look forward to rounding out my collection with some fill-in sizes soon.

Here’s a parting tip a friend suggested. While the handles are off, why not make a pattern by tracing around one of the handles on a piece of scrap. Label the pattern and store it in case you ever need to turn a replacement.

Chris Black makes cabinets, sharpens hand saws and sells old woodworking tools. Send him an email at redscabinet@gmail.com and follow him on twitter @chrislblack.

To see our full selection of Stanley Sweetheart chisels, CLICK HERE:

Over the years we’ve been asked numerous times if we carry children’s tool sets. Unfortunately, the quality of these sets marketed for children is so shoddy that the tools quickly break, or they are unusable to begin with. Like learning to play music on a cheap instrument, working wood with poorly constructed tools will soon frustrate even the most ambitious student. We recommend buying quality, age appropriate tools. Even if you purchase professional class tools, your investment can still be modest.

Over the years we’ve been asked numerous times if we carry children’s tool sets. Unfortunately, the quality of these sets marketed for children is so shoddy that the tools quickly break, or they are unusable to begin with. Like learning to play music on a cheap instrument, working wood with poorly constructed tools will soon frustrate even the most ambitious student. We recommend buying quality, age appropriate tools. Even if you purchase professional class tools, your investment can still be modest. As with any job, there's usually more than one way to do it. Instead of learning a specific technique, it's better to understand the principles behind the task, so you can problem solve when things don't work out. Resawing is the same way. You learn one method only to find out it doesn't work today on this piece of wood with this particular blade. Having a couple of techniques and understanding the principles of resawing will give you options during different circumstances.

As with any job, there's usually more than one way to do it. Instead of learning a specific technique, it's better to understand the principles behind the task, so you can problem solve when things don't work out. Resawing is the same way. You learn one method only to find out it doesn't work today on this piece of wood with this particular blade. Having a couple of techniques and understanding the principles of resawing will give you options during different circumstances.

Let me start off by saying I’m not an engineer, although I did flunk out of engineering school and join the Army. I’m also not a trained metallurgist, but I have done quite a bit of blacksmithing and tool making. In fact one of my homemade jobs made it into an issue of Fine Woodworking. So when I say I tested a batch of Irwin’s new version of the Blue Chips, think woodshop, not laboratory. My test criteria basically consisted of me sharpening the chisels and using them over the course of a day as I would normally use my own bench chisels. Then, given my experience using hundreds of chisels over the years as a cabinetmaker, I decided if I liked them. You know, do they stay sharp, do they hold up, are they worthy or are they paint can openers.

Let me start off by saying I’m not an engineer, although I did flunk out of engineering school and join the Army. I’m also not a trained metallurgist, but I have done quite a bit of blacksmithing and tool making. In fact one of my homemade jobs made it into an issue of Fine Woodworking. So when I say I tested a batch of Irwin’s new version of the Blue Chips, think woodshop, not laboratory. My test criteria basically consisted of me sharpening the chisels and using them over the course of a day as I would normally use my own bench chisels. Then, given my experience using hundreds of chisels over the years as a cabinetmaker, I decided if I liked them. You know, do they stay sharp, do they hold up, are they worthy or are they paint can openers.