Sit back and enjoy this delightful video mini-history (with a beautiful musical soundtrack) of America’s forests from Colonial discovery through the 20th century, courtesy of Lee Tigner of Early American Furnishings in Dawson County, Georgia.

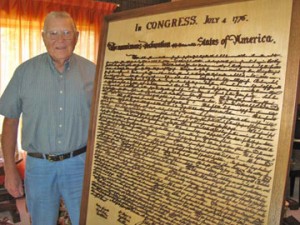

Local Man Carves into History with Declaration

By Kayleigh Karutis

For most people, any goal or pursuit taken up 10 years ago is probably a long-gone memory.

But for Charlie Kested of Johnstown, NY, there’s one thing that has been a constant in his life for the past 10 years. For the last decade, Kested has regularly sequestered himself away in his basement workshop, carefully carving, letter by letter, every single line of the Declaration of Independence out of dark walnut wood.

Times have changed. The popular music on the radio has evolved, as has fashion and television. Kested himself went through some changes, suffering a stroke that impaired his speech and his motor ability.

But throughout the years, the whirring of the blade of his scroll saw has remained constant, as has Kested’s unfailing patience for his work.

The massive piece, which is nearly as tall as Kested himself, was finally completed several months ago. It’s an exact wood model of the Declaration of Independence, right down to the flourish of John Hancock’s signature at the bottom. The dark walnut words are a stark contrast against the Baltic birch background.

The massive piece, which is nearly as tall as Kested himself, was finally completed several months ago. It’s an exact wood model of the Declaration of Independence, right down to the flourish of John Hancock’s signature at the bottom. The dark walnut words are a stark contrast against the Baltic birch background.

It was a labor of love that Kested said he knew he would eventually complete. The time spent on the piece paid off, when he was awarded first place and best in show at the 2010 Florida State Fair.

The 81-year-old retired industrial arts teacher began experimenting in wood working when he was a child growing up in Fonda. Both his father and grandfather were accomplished woodworkers, he said.

“My grandfather had a lathe at home. I was maybe 10 when he got a box, stood me on it and put a tool in my hand. I did my first turn,” he said.

From then on, Kested showed an interest and skill in woodworking. He went into the Navy in the 1950s, where he attended wood pattern making school. He worked for years making models out of wood that would then be used to make cast-iron products for the Navy before returning home and becoming a teacher in the Fonda-Fultonville Central School District.

He’s made model medical prosthetics for replacement chins, noses and other body parts. He’s replaced the dashboard of an old Rolls Royce, and has worked making quality-control models for a variety of applications. He was looking for a special challenge, though, and found it in the Declaration.

He started the Declaration of Independence in 2000 and worked on it, little by little, over the years until it was near completion. A stroke, though, less than a year ago put the project, and his life, in peril.

He started the Declaration of Independence in 2000 and worked on it, little by little, over the years until it was near completion. A stroke, though, less than a year ago put the project, and his life, in peril.

Luckily, Kested emerged from his ordeal far better than some others do. He can no longer feel any sensation in one hand, but is able to still use it and still has a strong grip. His speech is slower and he sometimes struggles to find words, but ultimately he’s made a good recovery, he said. After some therapy he was able to resume work on his project, carving the final bits of punctuation and adhering them to the birch background.

He said he hopes his experience inspires others who deal with a similar issue.

“I feel really blessed. I want people to know that you can still do things, that they shouldn’t give up, they should keep on going,” he said.

Kested did keep on going, straight to the Florida State Fair earlier this year, where his piece attracted a lot of attention. Kested and his wife, Beverly, live in Florida during the winter months.

Peter Richardson, editor for the St. Petersburg Wood Crafters Guild in Florida, said the fellow woodworkers who saw Kested’s piece at the state fair were amazed by it.

“They understand the amount of patience and attention to detail it requires,” he said. “[Kested] is absolutely meticulous in his other pieces. [The Declaration of Independence piece] is so precise you can’t believe they were made my hand.”

Richardson called the piece “museum quality.” He said Kested’s stroke makes his accomplishment even more astonishing.

“It’s amazing when you understand that his right side was paralyzed,” he said. “He pushed and finished it and that alone deserved best of show.”

Aside from his prize-winning Declaration, Kested is an accomplished woodworker whose made everything from grandfather clocks to ornate, minutely-detailed decorations to jewelry armoires. His home in Johnstown is full of his work, from the entire kitchen to the “love spoon” adorned with roses he carved for his wife.

Beverly Kested said she is constantly in awe of her husband’s skill. She smiled as she warmly recalled when the pair first met while he was visiting the area to attend a wedding during his time in the Navy more than 50 years ago, and was eager to praise her partners accomplishments.

“He’s won so many awards, it’s unbelievable,” she said. “I think [the Declaration] is the best I’ve ever seen. I think he’s pretty special.”

Charlie Kested said the Declaration itself is a piece of history that is near to his heart. The document, written mostly by Thomas Jefferson and signed on July 4, 1776, declared the 13 American colonies at war with Great Britain, were no longer ruled by Great Britain and were independent states. It contains one of the most well-recognized lines in American history: “We hold these truths to be self-evident, that all men are created equal, that they are endowed by their Creator with certain unalienable rights, that among these are life, liberty and the pursuit of happiness.”

The Kested’s said Charlie’s work on the Declaration led them to learn more about the history of the document, which both called fascinating.

Now that it’s finished, it will remain in the Kested family as a treasured heirloom, the pair said. Kested said he isn’t taking a break from his woodworking now that his long-time project is finished. Next up, the Gettysburg Address. That piece, the pair said, will hopefully be ready for next year’s state fair.

This article first appeared on July 4, 2010 in The Leader-Herald, a newspaper in Gloversville, New York.

After getting an extraordinary amount of feedback on this article, we followed up with Mr. Kested by phone. You can see our latest report on Charlie Kested and his plans for the Gettysburg address here.

It’s always exciting around here when we receive a full 40-foot ocean container load of something we’ve ordered from abroad. Today we unloaded 70 Hofmann & Hammer workbenches from a container shipped direct from the factory in Gruenfeld-Zimmern, Germany. We believe they are truly the finest value in a premium quality workbench available anywhere. They’re now on sale on our website. Save $200 on the Large and Medium benches, and $100 on the compact bench.

Chris Black is shown demonstrating how to restore and sharpen an old handsaw in the Highland Woodworking booth at the Lie-Nielsen Hand Tool Event on Friday, May 7, 2010 at Peach State Lumber in Kennesaw, GA (20 miles north of Atlanta up I-75). Hands-on instruction in sharpening, tuning and using hand planes by Lie-Nielsen employees (including owner Tom Lie-Nielsen) is available throughout the day.

The show continues from 10 AM to 5 PM on Saturday, May 8. Admission is free.

Highland Woodworking is now the exclusive supplier for the Earlex 2900 HVLP Spray Station, which has brought a new level of performance and affordability to spray finishing.

Highland Woodworking is now the exclusive supplier for the Earlex 2900 HVLP Spray Station, which has brought a new level of performance and affordability to spray finishing.

The compact Earlex HVLP unit is an exceptional value with its aluminum spray gun, teflon-coated paint cup and 13 foot spray hose, all of which store neatly onboard the turbine unit.

HVLP technology now makes it easy for woodworkers and do-it-yourselfers to step up to spray finishing without the expense and steep learning curve once associated with spray finishing.

Our versatile Earlex 2900 HVLP sprayer comes equipped to apply a variety of finishes ranging from lacquers, varnishes, and polyurethanes to modern water-based finishes. Thinned latex paint can also be applied both interior and exterior.

Our versatile Earlex 2900 HVLP sprayer comes equipped to apply a variety of finishes ranging from lacquers, varnishes, and polyurethanes to modern water-based finishes. Thinned latex paint can also be applied both interior and exterior.

We supply the Earlex 2900 HVLP sprayer with a quick start guide as well as master finisher Jeff Jewitt’s excellent DVD and illustrated guide to spray finishing. The entire package deal is priced at only $149.99.

When we saw this jig demonstrated at the AWFS Show in Las Vegas last summer, our first thought was “Who needs another specialized router table jig?”

Boy, were we wrong! Kreg’s new Beaded Face Frame System has taken off like you cannot imagine. Simply put, it easily produces cabinet face frames that feature attractive professional-looking beads that connect flawlessly around the entire frame. It’s either doing the work of a specialized machine that would otherwise cost thousands of dollars, or it quickly and efficiently replaces a long and laborious tablesaw project plus tedious assembly.

John Lucas has provided a detailed illustrated tutorial on using the jig on his website Wood Shop Demos.

We also have a 3-minute video demo of the tool in action.